How satisfied were

you with

Rudrra Sensors??

Tank Weighing Load cell

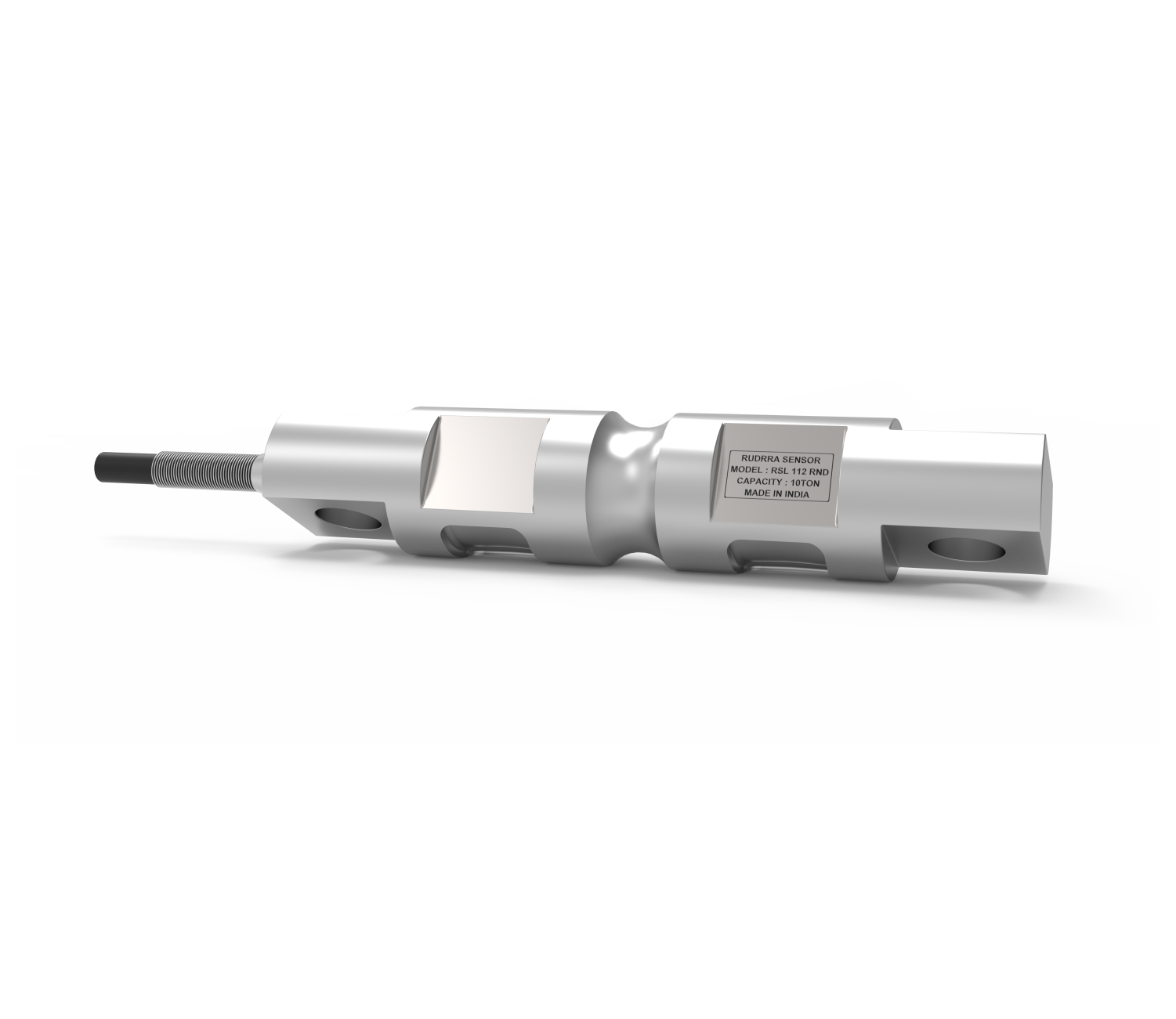

Order Online the Best RSL-112-RD in India

Rudrra Sensor is a manufacturer of a comprehensive range of products, including the RSL-112-RD Dual Shear Beam Load Cell. In the construction of the Dual ended load cells, the use of superior quality materials ensures that notable characteristics such as the RSL-112-RD's tremendous tensile strength and persistence are achieved, among other things. Furthermore, consumers are pleased with the opportunity to have it in a variety of configurations at a reasonable price, as previously said.

This is an excellent opportunity to combine two single-ended load cells into a single practical tool, which has the advantage of higher loading capacity as well as greater resistance to RSL-112-RD off-center loads and side forces

High capacity installations such as silos, tanks, truck scales (weighbridges), railway scales, and other heavy industrial operations are the most common applications for the RSL-112-RD twin shear beam load cells.

ABOUT US

We are Rudrra Sensors, and we are the best load cell and load indicator manufacturer in India. We not only create the best quality RSL112 RD sensors and other sensor equipment of the finest quality, but we are also the most reliable supplier of load cells and indicators.

In addition to the best quality RSL 112 RD sensors in India, Rudrra is a leading manufacturer and supplier of the finest quality load cells and indicators to businesses and customers in India and across the continent. In the field of precision manufactured load cells, pressure transducers, and load indicators, Rudrra Sensors is one of the top manufacturers and suppliers in the world. We give a product that is both innovative and long-lasting, with no negative consequences.

Contact us if you have any questions or concerns of any kind.

Key Features :

Capacity ranges from 5Tf to 100 Tf

Triple-Sealing

Electro less Nickel Plating is available.

Applications :

Weighing of trucks, tanks, and hoppers

Tensile Testing (also known as tensile strength testing)

Weighbridge

Optional :

Digital Load cell

Stainless steel structure

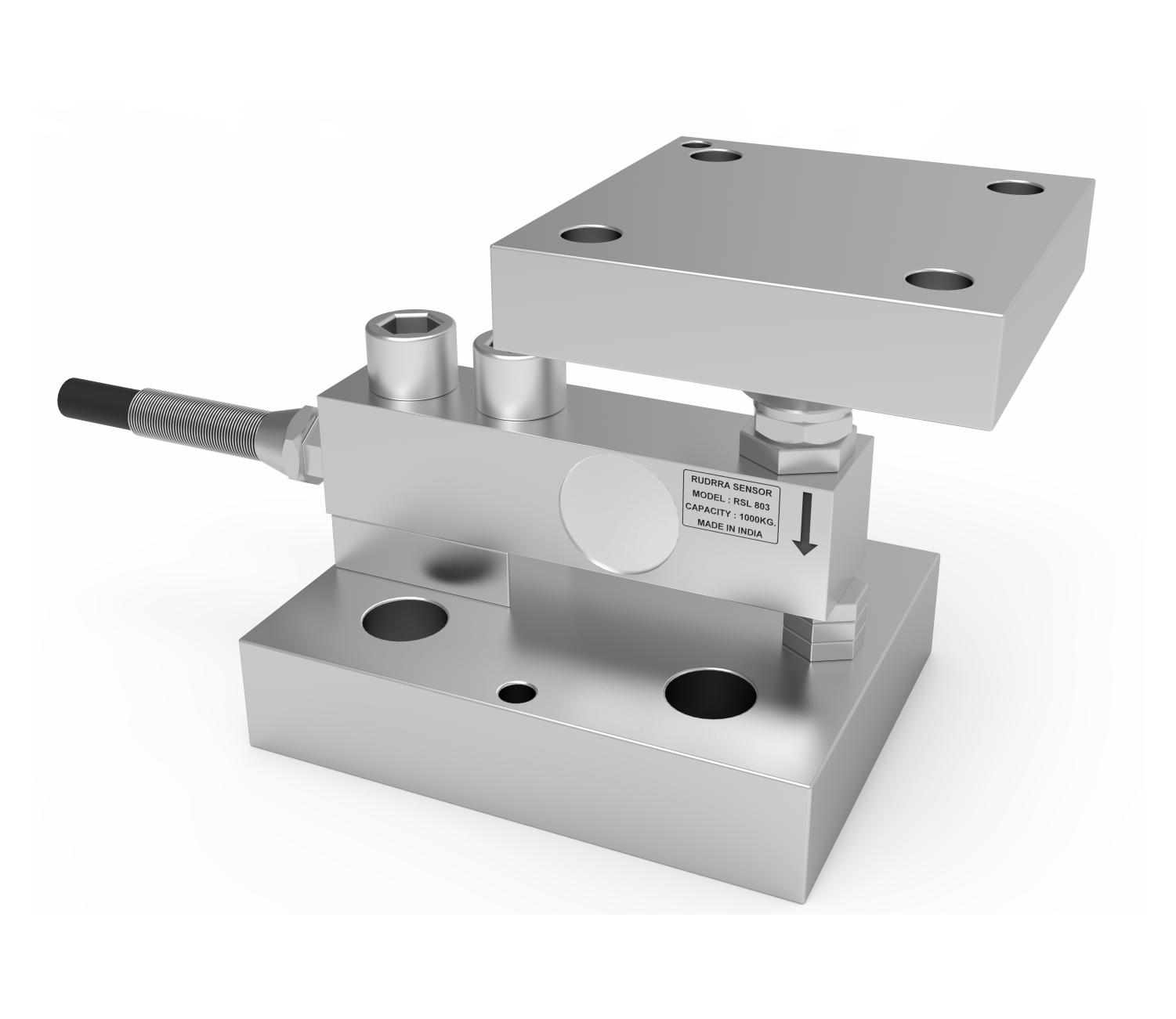

Load cell mounting assembly provided on request.

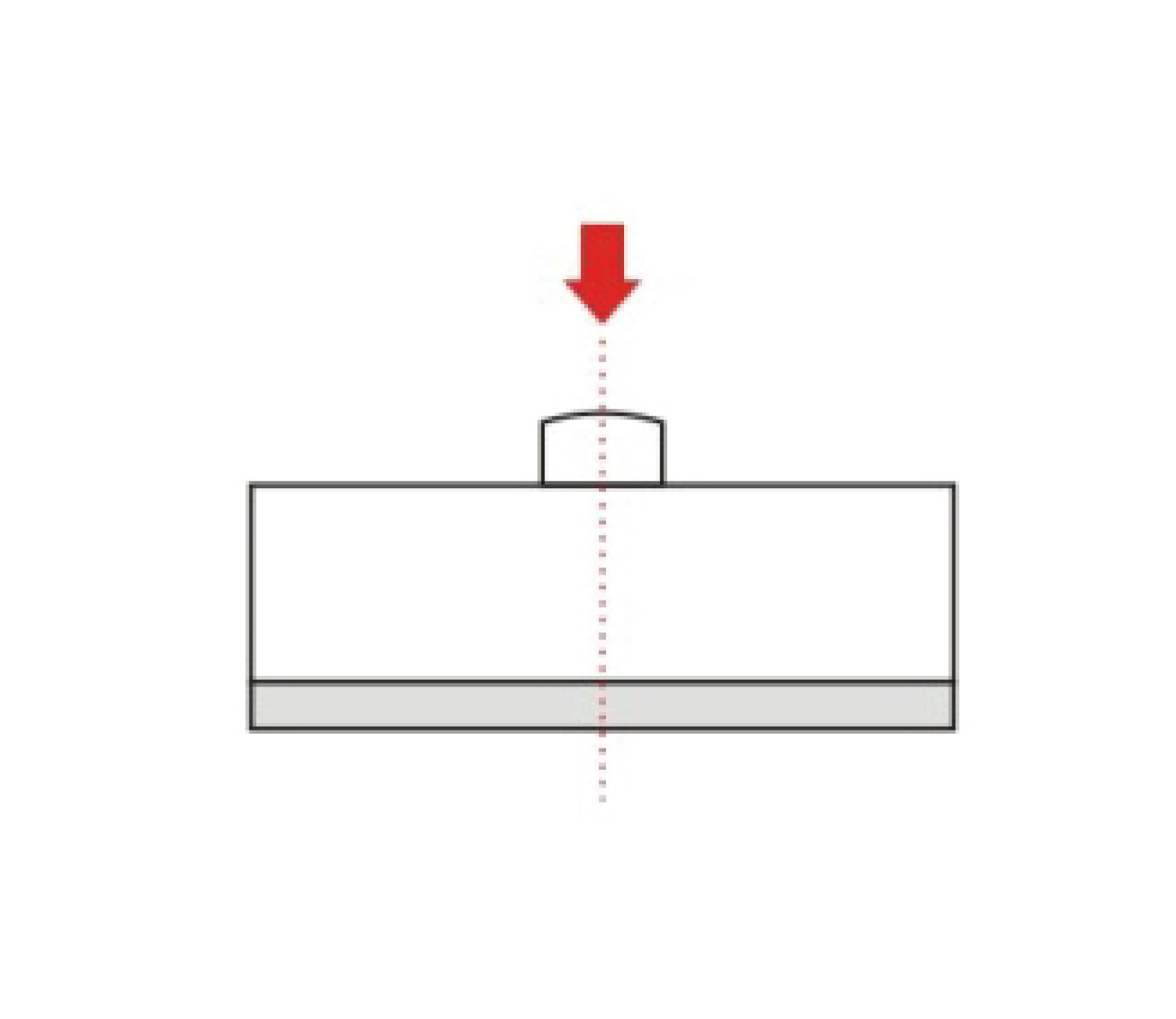

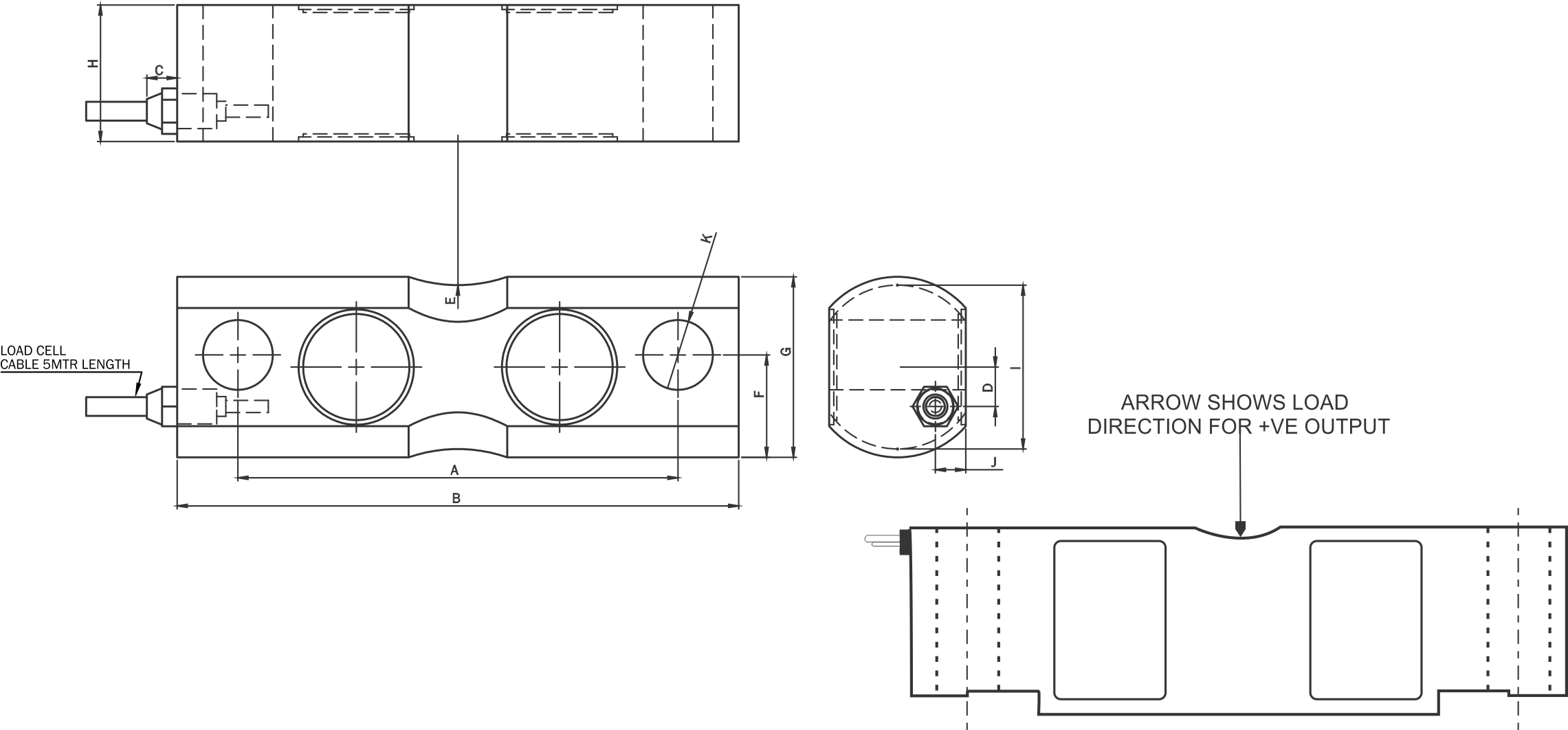

Load Application Layout :

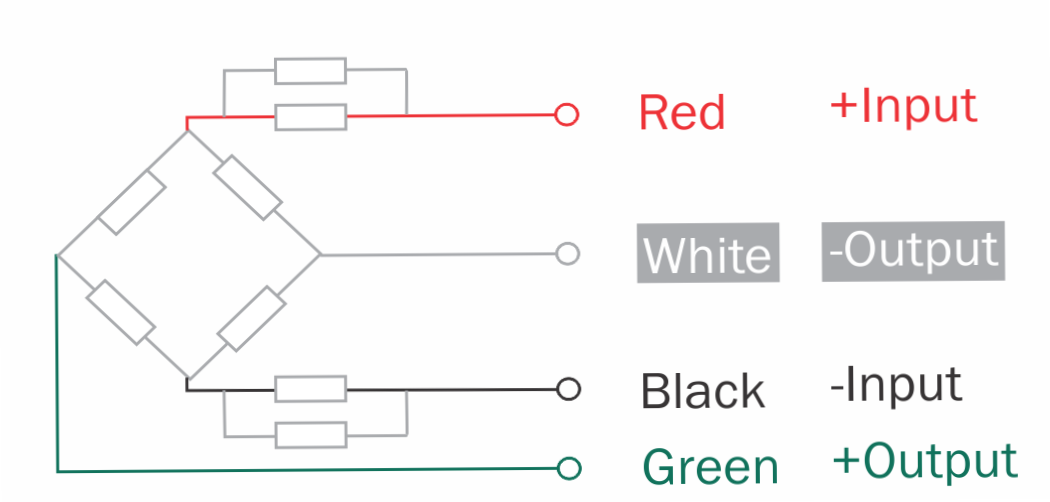

Cable Connection Details :

Dimensions :

CAPACITY | A | B | C | D | E | F | G | H | I | J | K |

5T,10T,20T | 145 | 185 | 20 | 13 | 50 | 33.8 | 59.5 | 45 | 54 | 10 | 23 |

30T to 50T | 220 | 285 | 20 | 16 | 50 | 44.8 | 74.5 | 60 | 65 | 12 | 30 |

Parameters :

Standard Capacities (tf.) 5 / 10 / 20 / 30 / 50

FAQs about Tank Weighing Load Cells

What is a tank weighing load cell?

A tank weighing load cell is a sensor used to measure the weight of liquids or solids stored in tanks, silos, or hoppers. It enables precise inventory control, batching, and material flow monitoring by converting the tank’s load into an electrical signal.

How do tank weighing load cells work?

These load cells are installed beneath or on the support structure of the tank. As the tank is filled or emptied, the load on the sensors changes, and the resulting electrical signal is processed to display the exact weight of the contents inside the tank.

What type of load cells are used for tank weighing systems?

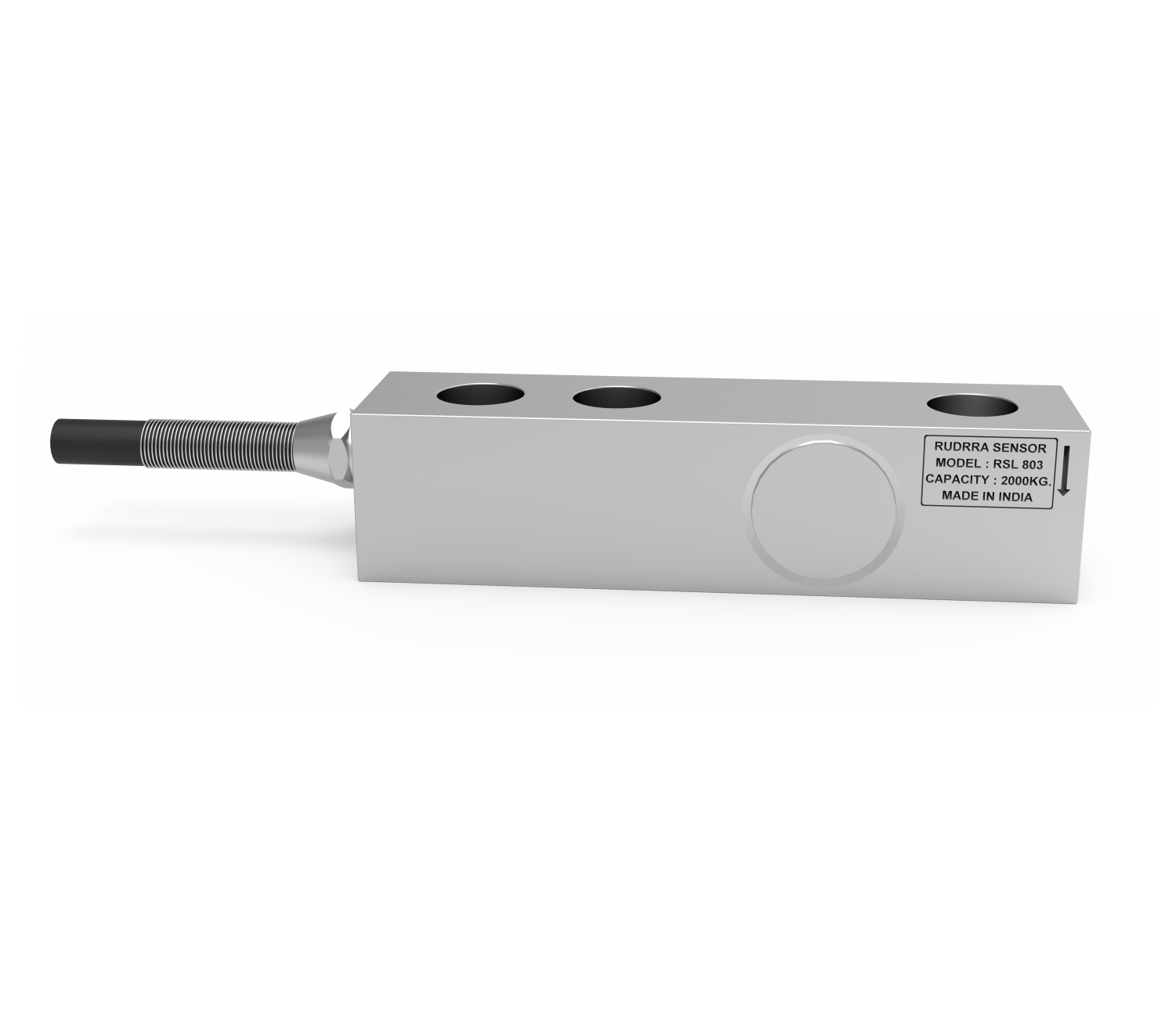

Common types include compression load cells, shear beam load cells, and bending beam load cells. The choice depends on tank size, mounting type, load distribution, and environment.

How many load cells are required for a tank?

Typically, 3 or 4 load cells are used for smaller tanks to ensure stability and accurate weight distribution. Larger silos may require more load cells to handle heavier loads and maintain accuracy.

What are the advantages of using load cells in tank weighing?

Tank weighing load cells provide non-intrusive, continuous, and accurate measurement. They eliminate the need for level sensors or flow meters and can handle a wide range of materials without direct contact with the product.

Can load cells be installed on existing tanks?

Yes, load cells can be retrofitted onto existing tanks using mounting kits and load cell assemblies. Careful installation and calibration are essential to ensure proper performance.

Are tank load cells affected by temperature and vibration?

Environmental factors like temperature fluctuations, vibration, and wind loading can affect accuracy. However, most industrial load cells come with temperature compensation and anti-vibration mounting options to minimize these effects.

What materials are tank load cells made from?

They are commonly made from stainless steel or alloy steel, offering strength, corrosion resistance, and long-term reliability, especially in food processing, chemical, or outdoor environments.

How accurate are tank weighing load cells?

High-quality tank load cells offer accuracy within ±0.05% to ±0.1% of full scale. Proper installation, calibration, and leveling are key to achieving optimal accuracy.

Do tank weighing load cells require maintenance?

Regular maintenance involves checking mounting hardware, inspecting for corrosion or physical damage, and recalibrating the system periodically to ensure reliable performance over time.

What is a tank load cell mounting assembly?

It includes the load cell, base plate, top plate, and restraining hardware. These assemblies help distribute weight evenly and protect the load cell from side loads, uplift, and overload conditions.

Are explosion-proof or hygienic models available?

Yes, ATEX-certified load cells are available on request with extra cost for hazardous zones, and hygienic, wash-down models are used in food, dairy, and pharmaceutical applications for safety and compliance.

Download PDf File

Download PDf File