How satisfied were

you with

Rudrra Sensors??

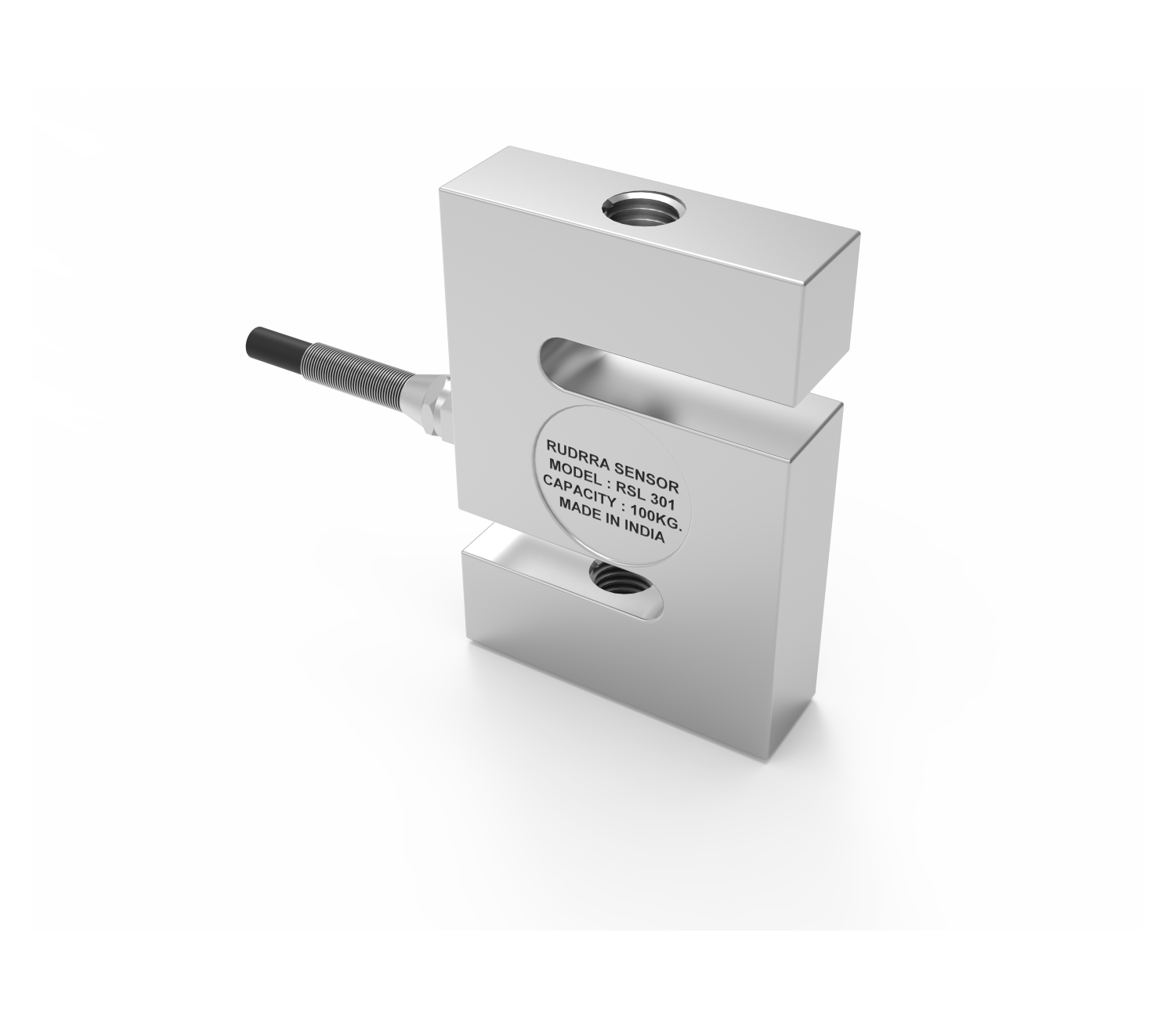

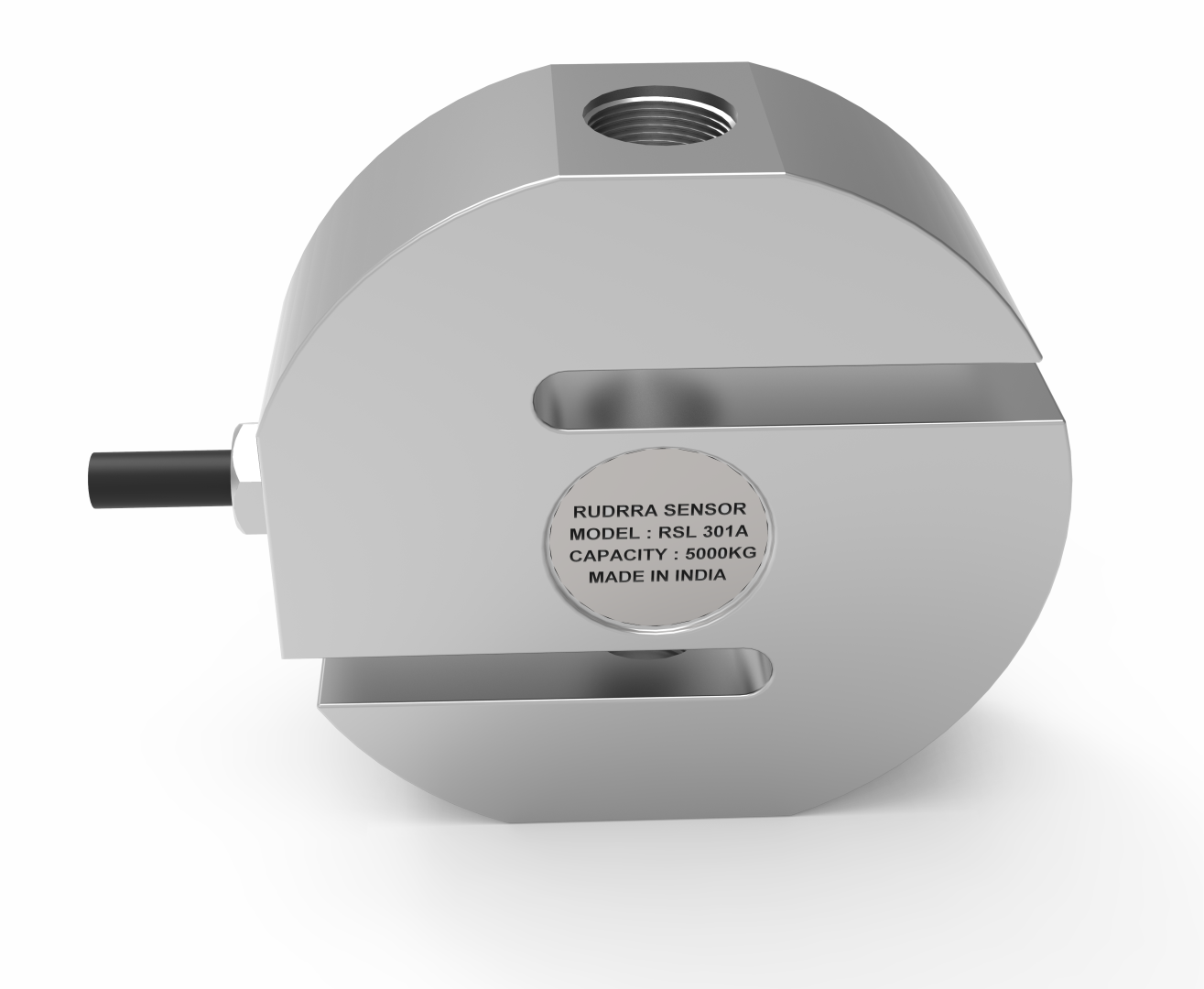

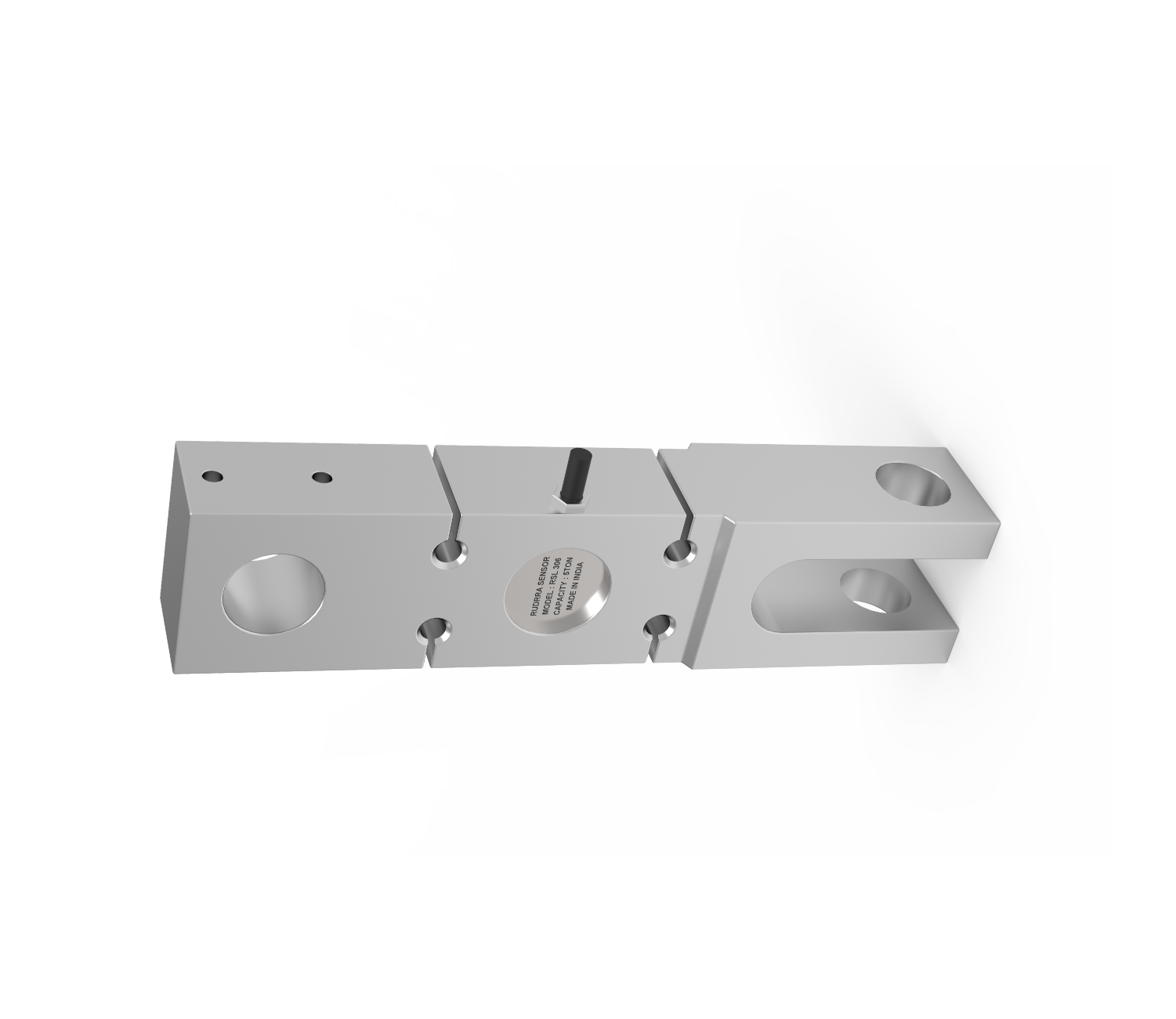

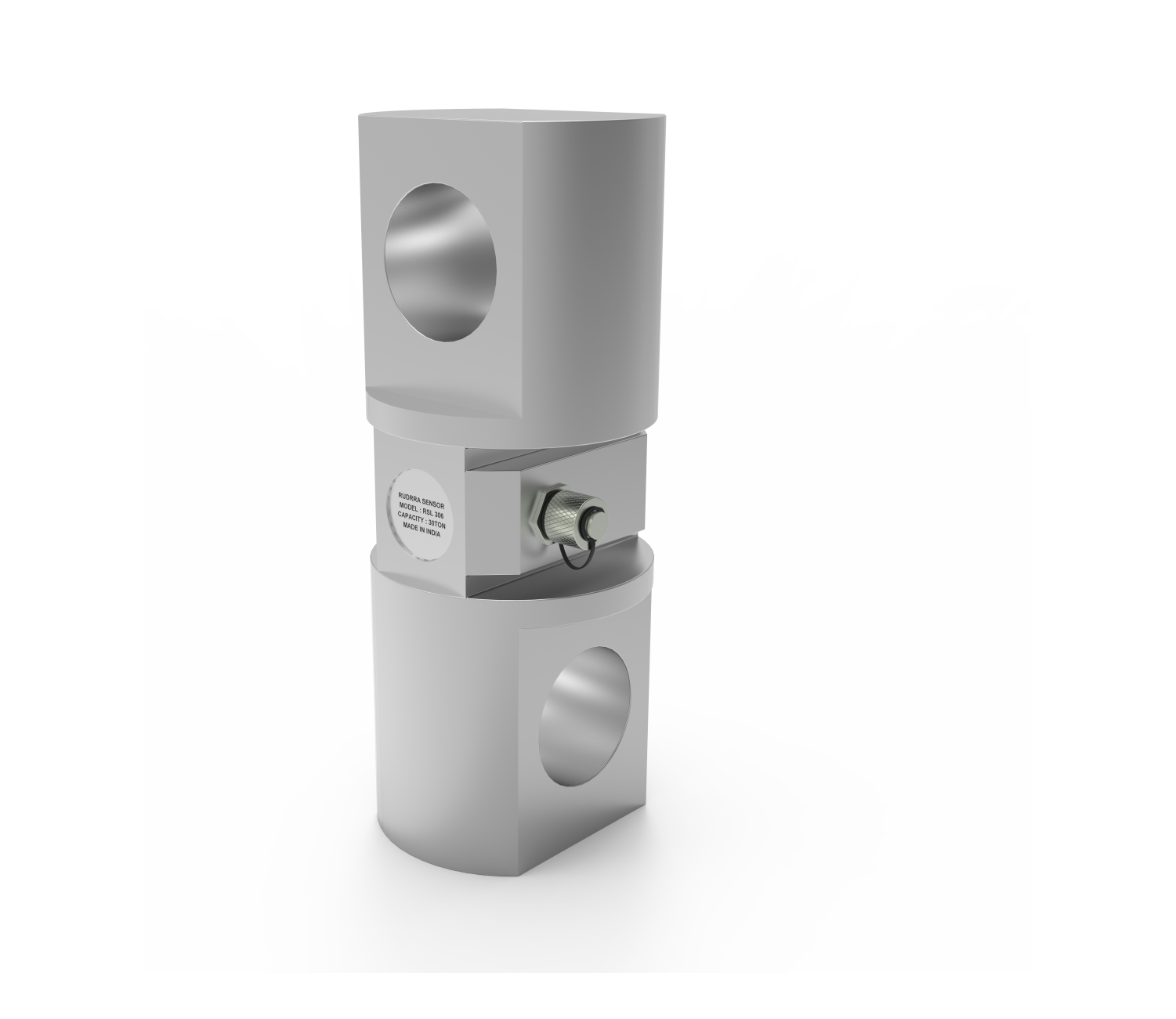

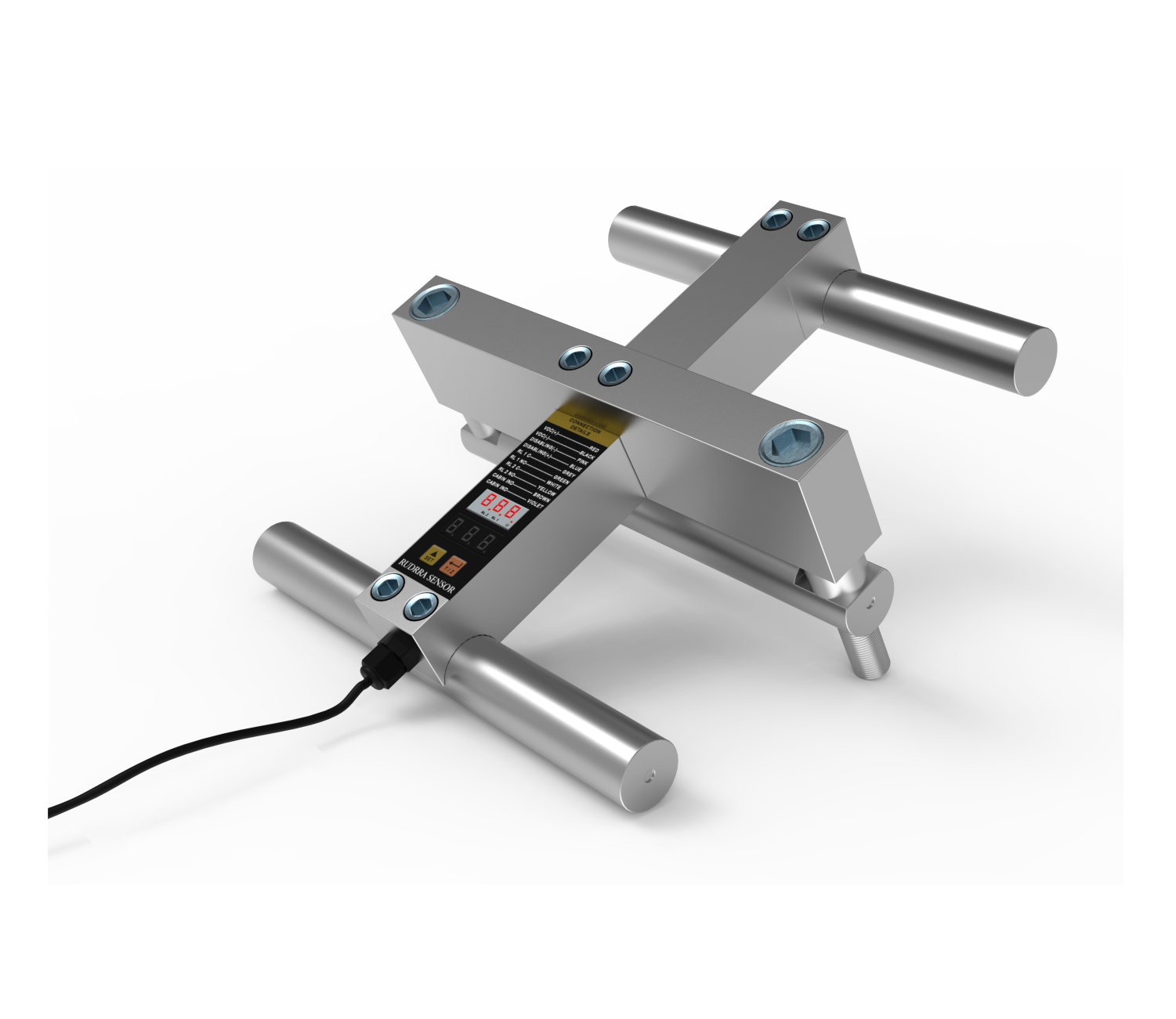

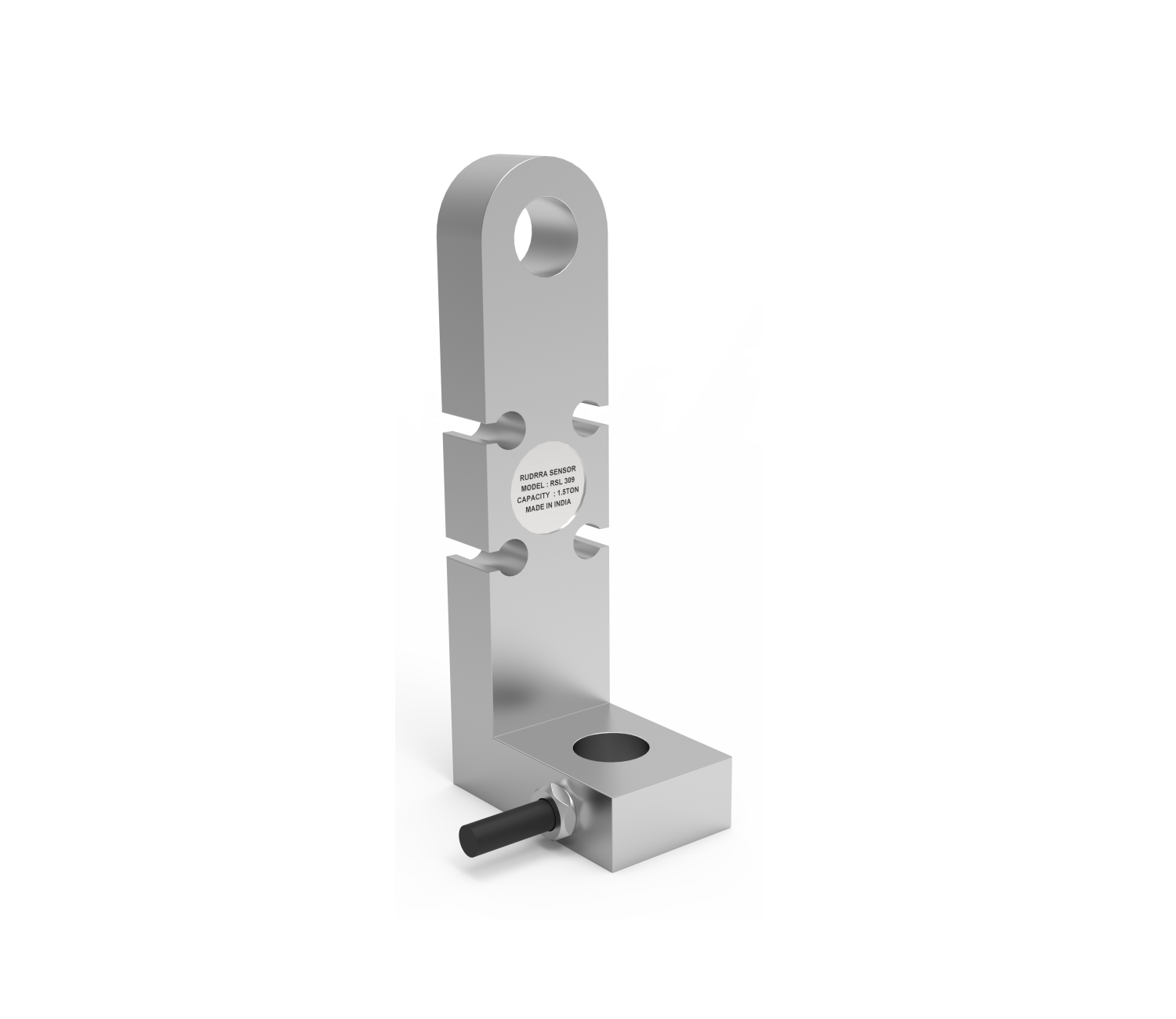

S TYPE LOAD CELL

What is S-Type Load Cell?

S-type load cells basically receive tension, pressure or compression output readings. It is used in many places for example tank weighing, hoppers, truck scales, suspended loads, etc. As the name suggests the load cell has a shape similar to the English alphabet ‘S’. The capacity of S-type load cells generally extends from 25kgs to up to 30tonnes. S-type load cells use metal foil strain gauge technology. There are many reasons to prefer this load cell as it offers accuracy as well as compact design features. To enhance the performance of S-type load cell, it should be installed using rod ends or load buttons. This enables the cell to perform outstandingly in tension as well as compression applications.

Normally, the S-type is preferable to work in tension applications where static as well as dynamic loads are involved. Its main application involves converting mechanical scale into electronic scale and weighing big objects like cranes or big bags, etc.

Since S-type load cells are basically manufactured to serve industrial requirements and to serve different applications, they are made strong enough to withstand ambient conditions. This means that they are made in a way or made with such elements that they don’t easily expand due to extreme heat or contract due to extreme cold. S-type load cells fulfill and meet the requirements of IP65 and IP68.

Specification of the S Type Load Cell

- The body of the cell is generally made up of the elastic but the strong metal. Alloy steel, aluminum, or stainless steel is used for making the load cell.

- The strain gauge is made in such a way that it has a very thin wafer-like body with a good conductor of electricity.

- The conducting wire is put connected with the strain gauge to carry electric changes.

- Every S type load cell comes with the fixed nominal output with the fixed excitation voltage it also has the fixed input and output resistance.

- It is also necessary for the producer of the load cell to mention the environment protection class of the cell.

- Some cells come with IP67 protection while some with IP68.

- The IP rating is for how good is the product against environmental factors like dust and airborne, rain, liquid, for how long it can work without any issue if it gets to immerse in the water up to 1 meter, etc.

- The higher the rating the better performance the product gives.

Design and Construction of S Type Load Cell

S type of load cell is shaped in the English S alphabet. They generally have the spring element. The spring element is made up of elastic metals. The reason for making spring elements from elastic metal is wherever force is applied on the load cell due to force its shape may get deformed so if we use inelastic metals the deformed shape won’t get restored after the force is removed. The spring element of S type load cell is made up of aluminum or steel. These metals are famous for their extreme strength and have very good elastic properties. So the spring element not only makes sure the cell's body keeps in form but also gives support to the string gauge.

The strain gauge is placed at the center of the S type load cell. Strain Gauge is a conductor of electricity. It converts the pressure or the force applied on it into the electrical signal. And according to that signal, the force or pressure it is on gets calculated. The cell has the conducting wires for the conduction of the electricity which are connected to a strain gauge which then puts up on the measuring batter. The S Type load Cell has the two threaded holes at the top and the bottom of the cell. Those cells are used for mounting the objects with the thread or with wire. We can even put the weighing object at the top or the bottom side of the S type cell it can measure it.

Working of the S Type Load Cell?

The working of the load cell depends on the strain gauge. When pressure or force gets applied to a strain gauge its resistance gets change. Be it a tension force or the compression force. As seen earlier due to compression the strain gauge gets compress and due to tension, it gets to expand. A strain gauge is a conductor so obviously, it has its resistance. But due to force or pressure, it gets changed, and with the help of that changed resistance, the force or the pressure which gets applied to it is calculated. S type Load cell work on the principle of the Wheatstone bridge.

In the Wheatstone bridge, an electric input is applied to the four resistors which are arranged in with two resistors on the left side and two on the right side. They are arranged in such a way to give the null value in the center. The Wheatstone bridge is developed by the scientist Charles Wheatstone to measure the unknown resistor if we know the value of the three resistors. In the load cell this circuit is used and on the four ends of the circuit where the resistor is gets attached the strain gauges are put. So when the load is applied on the cell it either cause the tension or the compression on the load cell so the resistance of the four strain gauge gets changed which can be calculated and the weight will be known.

Popular Applications for S Type Load Cells

S Type Load Cells are used in a variety of applications. As previously said, S type load cells are typically utilized for mechanical-to-electrical scale conversions, but they are also used for a variety of other purposes. Listed below are some of the more common applications for S type load cells that we have come across.- Scales that hang from the ceiling

- Machines for dynamometer testing,

- Such as hopper scales

- Crane scales,

- Tank weighing,

- Mechanical overload prevention,

- Structural performance testing,

- Material strain testing,

- Industrial control and feedback,

- And industrial food processing.

Advantages of S Type Load Cells.

Small size:

The S type load cell has a small size which makes it easy to carry around. Any construction worker or any worker dealing with the weight of the product can measure the weight and can also carry it anywhere.Very high tolerance:

Due to the product used to make the cell, S shaped load cell has very high tolerance within it. It can endure for a long time without any deformation.Can be used for both tension and compression:

This is one of the most important advantages of the S type load cell. Due to the structure of the strain gauge, the cell can be used for measuring the weight of objects with the tension force similarly can be used to measure the weight of an object with compression force.Can be used in any environment:

Due to the high IP code, the cell can be used in any environment. We can use it in a rainy environment or we can use it in the desert environment it will perform the same.Comes with different weight range:

Every industry works with a different weight range. If we talk about the construction industry they work with very heavy loads, the mechanical industry also works with heavyweight products while the small business also needs any instrument to weight their product. Further, s type load cell price is very affordable. It is practically useless if all the industry used the same instrument for measuring their product. Hence with the S type load cell, every industry can weigh their product due to their different weight variant.Easy to use:

The S type load cells are comparatively easy to use. No complex method involves measuring the weight with the load cells. With just the basic understanding of its working, anybody can use it. Hence, many industries buy S type load cell for various applications.The S type load cells that we have available can be found in the load cell area of our website under the load cell category. Many of these are approved by the OIML and the NTEP. For all of the load cells on our website, datasheets are accessible to download and review.

About Us :

Aside from that, Rudrra Sensors is a leading producer, supplier of high and premium-grade load indicators with both manual and automated tare control options. Because of the way bending beam load cells are constructed, some portions of the load cell body flex or curve in response to the application of a load. Applied Technologies is a leader in the manufacturing of precision load cells, pressure transducers, and load indicators. Load Masters is one of the top manufacturers and suppliers in the world.

Contact us if you have any questions or concerns of any kind.

Rudrra is a prominent company engaged in providing the world class S Type Load Cell. The unique features of this product are having the S Shape & its variable used in many industries. We use high graded stainless steel materials to make this product. The quality of the product can be judged from its long lasting & rust resistance. We have professional team, who can carry out the demands of such products in the market.

It is very easy to use & install. It is mostly used in small & medium platform scales.

We are located at India & able to cater the needs of all states of different regions.

We have different models/designs in the products which are mentions as below.

S Type Load Cell Price

| Model | S Type Load Cell – RSL 301A |

| Price | ₹4500 to ₹7500 |

| Capacities | 10 kg, 20 kg, 30 kg, 50 kg, 100 kg, 200 kg, 300 kg, 450 kg, 500 kg, 750 kg, 1000 kg (1 ton), 2000 (2 ton), 3000 (3 ton), 5000 (5 ton), 10000 (10 ton) |

| Weight | 1 kg, 2 kg, 3 kg |

| Delivery | 2 to 7 Working Days |

Features :

Low cost and excellent performance at the same time

It is positioned on the side

For electrical interface, a 6-foot strain-relieved integrated cable with pigtail leads that have been stripped and tinned is included with the kit.

There are standard full scale ranges of 50 to 500 kilos.

Only in tension is the calibration performed.

Application :

Vehicle structural performance testing, including testing of doors, hoods, and trunks.

The lifespan of an automotive component

Weighing

Shore hardness is a measure of how hard a surface is.

Polymers and elastomers are subjected to material strain testing.

Control and feedback in the industrial environment

Food processing on an industrial scale

Frequently Asked Questions

What is an S-Type load cell?

An S-Type load cell is a force sensor shaped like the letter “S”, designed to measure both tension and compression forces. Its versatile design makes it ideal for various industrial and testing applications where accurate bidirectional force measurement is required.