How satisfied were

you with

Rudrra Sensors??

Weighbridge Load Cell

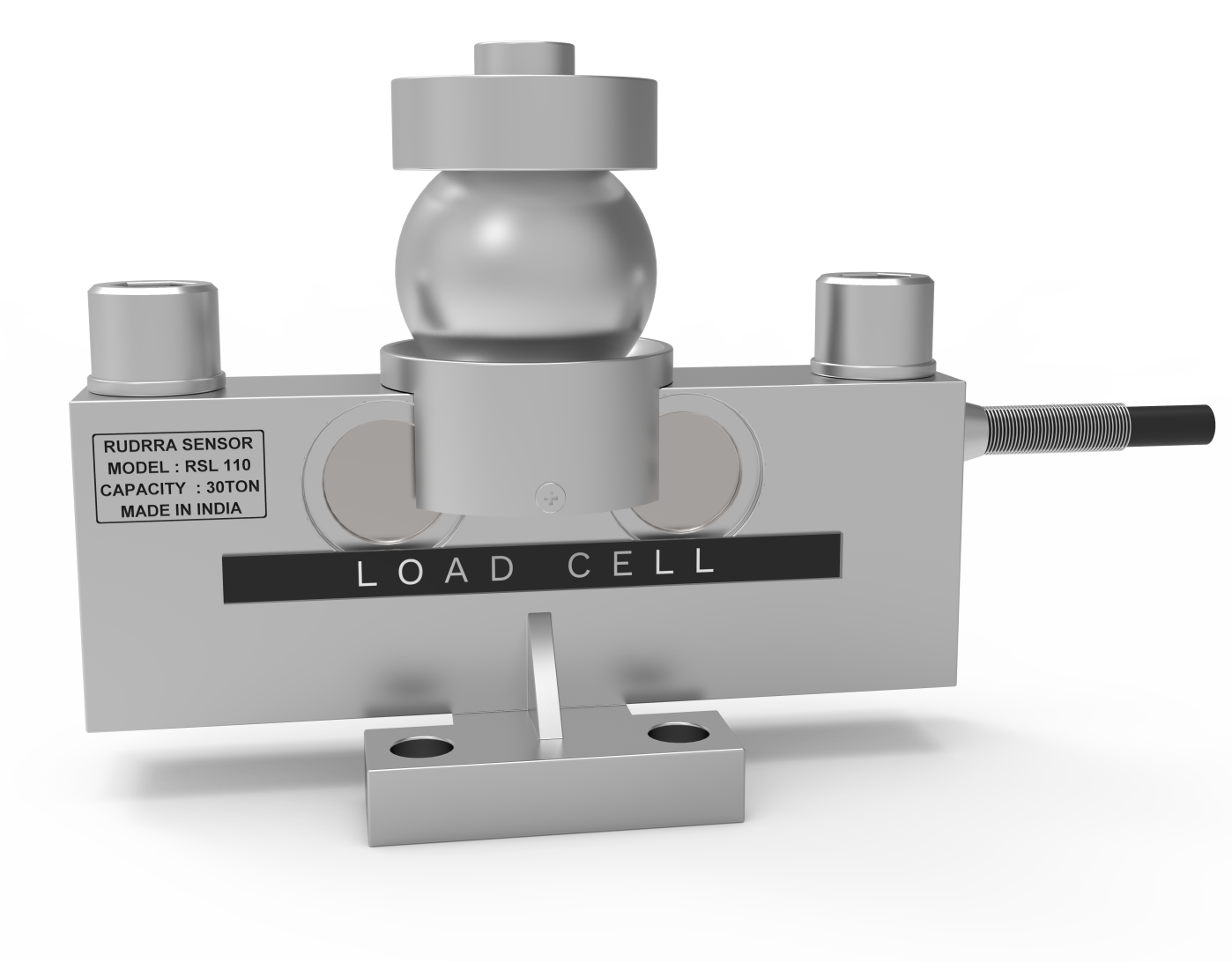

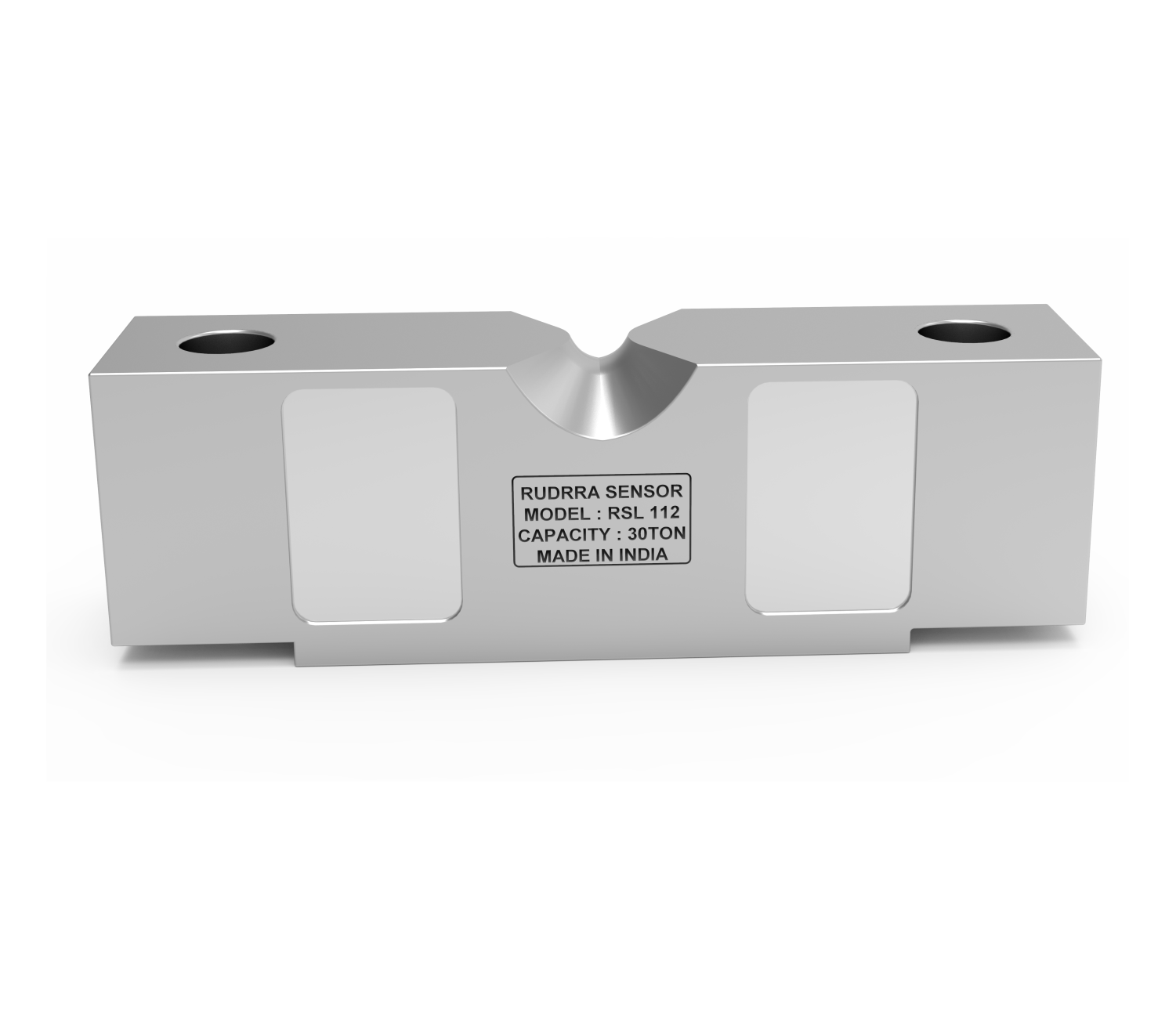

Designed and manufactured by Rudrra Sensors, the Double Ended Shear Beam Load Cell (RSL 110) is generally recognized as one of the most innovative products available on the global market. It enjoys a strong position in the market as a result of its exceptional alloy steel structure and unrivaled functionality.

It is a symbol of superiority in every way, and it is available in both adhesive and welded sealing options. It has a longer lifespan than the usual product, which can be attributed to the fact that it is compact.

Nickel plating is used on the new shear beam load cells, which makes them watertight and corrosion-resistant. This is a fantastic match for electronic truck scales of all kinds.

Load cells of the highest technological level are available in a wide range of models and combinations. Aside from that, it is custom-made to order. As the most well acknowledged supplier and exporter in the industry, we make certain that our ultra-modern load cell products not only satisfy the highest quality standards, but also set the benchmark in both the local and international markets as well.

ABOUT US

We are a leading load cell manufacturer in India. Based in Gujarat, we are one of the manufacturers and suppliers of sensors.

All of these things, including the tension in the ends of stay ropes, suspension lines, and railway catenary lines, can be measured. In the field of precision-manufactured load cells, pressure transducers, and load indicators, Rudrra Sensors is the best RSL 110 manufacturers and suppliers in the world.

There is no restriction on what you may talk about the product on this number. In addition, we also deliver a product of high quality.

Contact us if you have any questions or concerns of any kind.

Weighbridge Load Cell Price

| Model | Weighbridge Load Cell – RSL-110 |

| Price | ₹9500 |

| Capacities | 10000 kg (10 ton), 20000 kg (20 ton), 30000 kg (30 ton) |

| Weight | 8 kg |

| Delivery | 2 to 7 Working Days |

Features :

A wide range of capacities ranging from 100kg to 10000kg is available.

Alloy steel is used in the building

Environmental protection IP68 with hermetic sealing on all four sides.

Calibration in millivolts per volt

The design is low-profile

Applications :

Truck scales with electronic readouts

Hanging

Hopper weighing system

The level of the tank

Optional :

Digital Load cell

Stainless steel structure

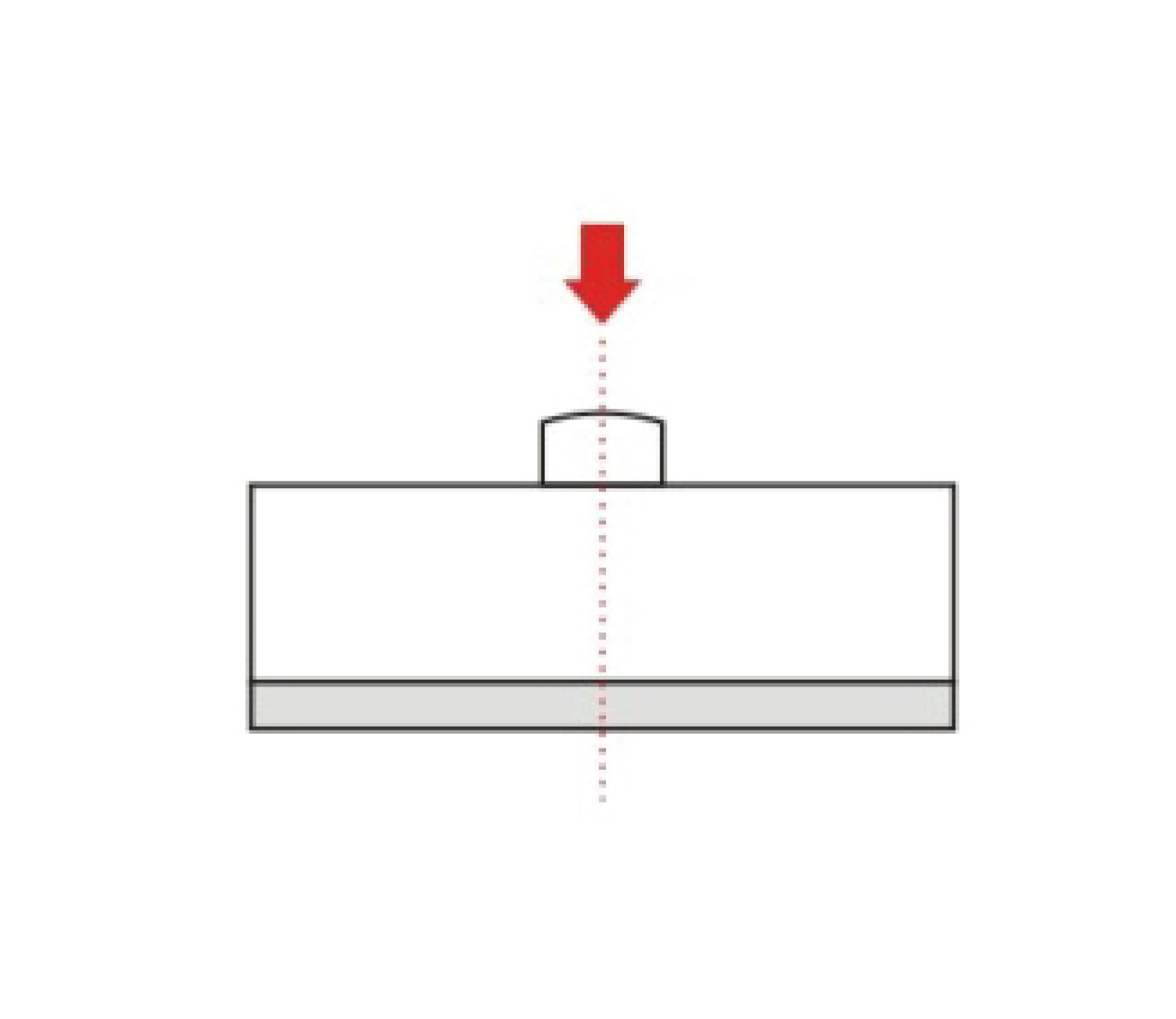

Load Application Layout :

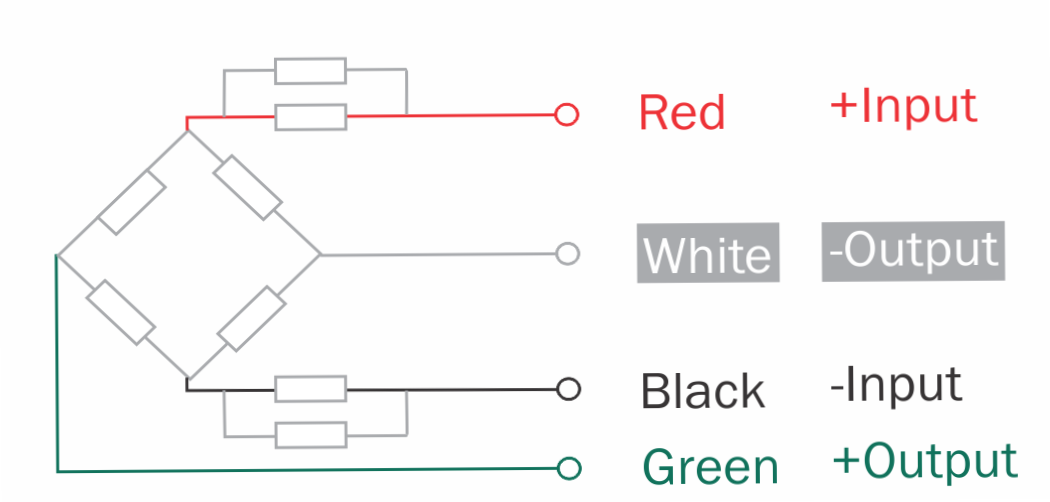

Cable Connection Details :

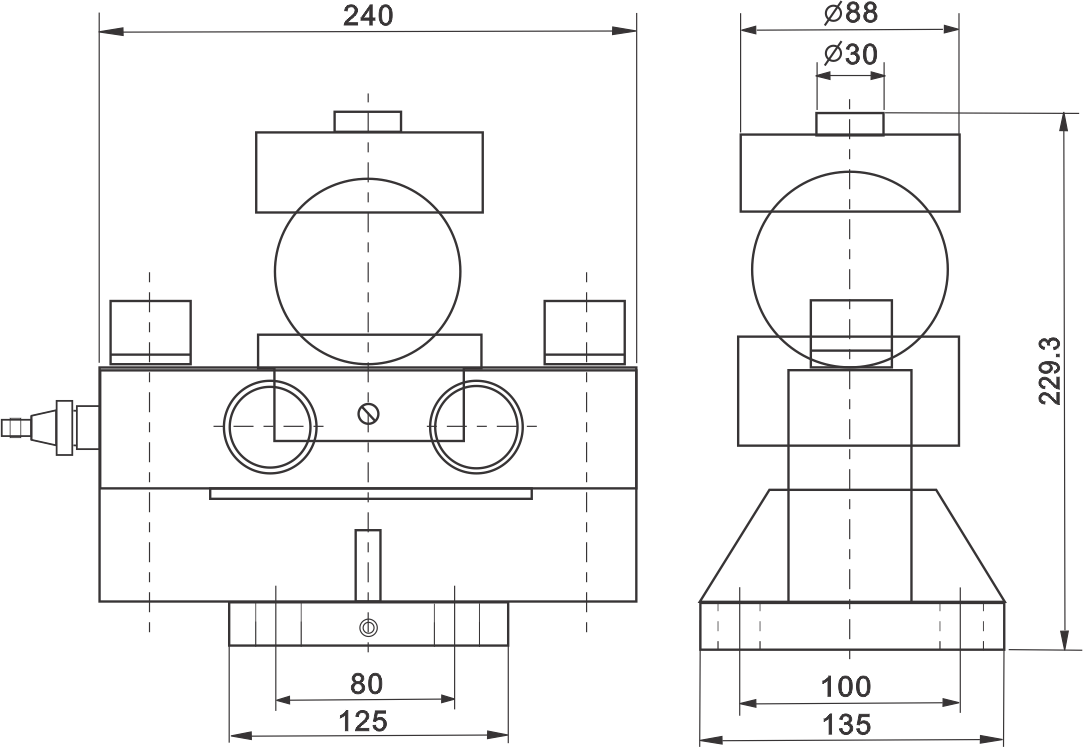

Dimenstions :

Parameters: (Analog Load Cell) Parameters: ((Digital Load Cell)

Related Load (Ton) 10 / 20 / 30 / 40 Related Load (Ton) 10 / 20 / 30 / 40

FAQs about Weighbridge Load Cells

What is a weighbridge load cell?

A weighbridge load cell is a precision sensor used to measure the weight of vehicles by converting the applied load into an electrical signal. It is the core component in a weighbridge system and ensures accurate and reliable weight readings for commercial and industrial applications.

How do weighbridge load cells work?

They work based on strain gauge technology. When a vehicle drives onto the weighbridge, the load cells beneath the platform sense the pressure or force applied. This force deforms the internal strain gauges slightly, producing a measurable electrical output proportional to the vehicle’s weight.

What types of load cells are used in weighbridges?

Common types include compression type load cells, double-ended shear beam load cells, and column-type load cells. The selection depends on the design and capacity of the weighbridge. Compression load cells are the most widely used in truck scales.

How many load cells are used in a weighbridge?

Typically, a standard weighbridge has 4 to 8 load cells, depending on the size and design. Each load cell is placed at the junction where the deck meets the foundation to ensure accurate distribution and measurement of vehicle weight.

What is the capacity of a weighbridge load cell?

Capacities can range from 10 tons to 50 tons per cell, depending on the expected vehicle loads. The total capacity of the weighbridge is calculated based on the number of load cells and their individual ratings.

Are weighbridge load cells weather-resistant?

Yes, weighbridge load cells are designed to withstand outdoor conditions. They typically come with IP67 or IP68 protection, stainless steel housing ( optional ), and sealed construction to resist water, dust, and harsh environmental factors.

How accurate are weighbridge load cells?

Modern weighbridge load cells provide high accuracy, often within ±0.02% to ±0.05% of full-scale output. Accuracy can vary depending on calibration, installation, and environmental conditions.

How often should weighbridge load cells be calibrated?

It’s recommended to calibrate the load cells annually or whenever there’s a noticeable discrepancy in readings. Regular calibration ensures compliance with legal-for-trade standards and maintains measurement accuracy.

Can weighbridge load cells be repaired or replaced?

Yes, faulty load cells can be replaced individually without changing the entire weighbridge. However, it’s important to use compatible models and perform recalibration after replacement for consistent performance.

What are common signs of load cell failure in weighbridges?

Symptoms include inaccurate readings, drifting weight values, no signal output, or sudden drops in weight display. Physical damage or water ingress can also cause failure.

How to protect load cells in a weighbridge?

Protection methods include lightning arrestors, waterproof junction boxes, anti-vibration mounts, and surge protectors. Regular maintenance and visual inspections also help prevent premature damage.

Are digital weighbridge load cells better than analog?

Digital load cells offer faster response, improved accuracy, and easier diagnostics, while analog load cells are cost-effective and widely supported. Both have their advantages depending on application and budget.

Download PDf File

Download PDf File